Damascus steel, finest luxury

We remind you that the advice and descriptions given are valid only in the context of a normal use of your knife. It is not a screwdriver or a can opener! And of course, washing in a dishwasher is strongly discouraged, as it will damage both the blade and the handle.

To maintain your blade, a simple wipe is enough. For the maintenance of the mechanics, a few drops of specialized oil are enough. In addition, beyond a regular sharpening, a more "intensive" sharpening is recommended once a month (with a whetstone or a diamond sharpening steel according to your convenience).

There is no secret, for your knife to keep its splendor and efficiency over time, it must be maintained.

Damascus steel story

Behind the contrasting patterns of this technique, well known and loved by knife enthusiasts, lie centuries of know-how. Even if its origin remains unclear and divides historians, we know that Damascus steel was born in the Persian Gulf region several centuries before Christ. And already in the history its robustness was noticed on the battlefield, conferring even a certain advantage to the warriors possessing a Damascus blade.

Its notoriety has continued to grow, it was used in its early days, in addition to swords, in the manufacture of spears or daggers. Its arrival in Europe is rather late since it is necessary to wait for the crusades for the damascus steel to dazzle the old continent. The qualities sought were already at the time a high quality of cut and resistance to use for the manufacture of spears or swords. These Damascus steel objects were already rare tools and made by the best blacksmiths. The beauty of these blades has become over the centuries a true myth for the different peoples who used them.

Manufacture of Damascus steel

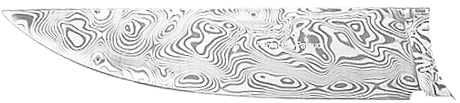

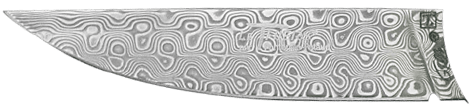

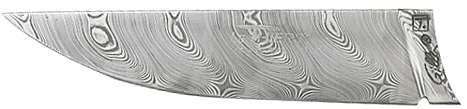

The traditional manufacture of Damascus steel consists of welding two different steels, usually in seven layers. Then it is a question of folding these layers over each other and to repeat the operation until obtaining at least a hundred of layer.

The making of a Damascus blade requires know-how, but also patience and of course a good dose of passion. These three ingredients are necessary to reproduce with precision the beautiful patterns that characterize it, the result of the superposition of thin layers of steel.

The properties of damascus steel

When we talk about Damascus steel, the first thing that comes to mind is aesthetics. Damascus steel is to cutlery today what gold is to jewelry. Its exceptional technicality offers you the possibility to choose different contrasting and sophisticated patterns for your blade:

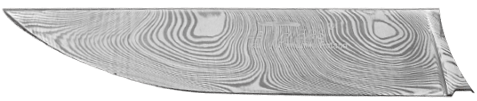

Damas Vinland

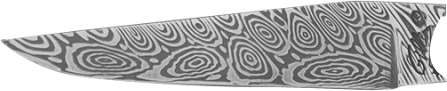

Damas Rose

Damas Twist

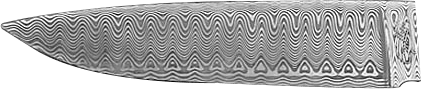

Damas Sparse Twist

Damas Heim

Damas Hugin

Despite its superb quality, like all steel, Damascus has a few drawbacks

Its high price explained by the price of the raw material and the important working time on each blade.

But beyond the aesthetics of the patterns, Damascus steel is a robust steel with an incredible cutting edge.

We only offer Swedish Damascus stainless steel by Damasteel®, which is produced by powder metallurgy and which we know and have tested.

This very particular technique consists in making a steel by sintering contrary to the traditional technique by fusion.

Sintering consists in heating a powder until it melts in order to make an alloy of different steels. This makes it possible to obtain very technical steels: better mechanical resistance, easier to machine, high stability...

These steels keep their superb appearance over time thanks to their stainless steel properties. Be aware that "traditional" Damascus carbon steels lose a lot of their aesthetics with use, which is frustrating for a knife that you have paid a certain price for. And like all carbon steels, if not carefully wiped down after use they can rust.

There is another type of metal for your blade, often referred to as Damascus, from a Japanese technique called Suminagashi.